Needle punching with thermal bonding

- Home

- Technology

- Needle punching with thermal bonding

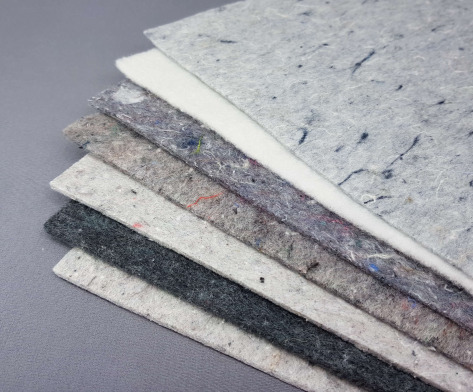

WHAT IS NEEDLE PUNCHED AND THERMAL BONDED NONWOVEN?

The needle punched nonwoven can become stiffer, smoother and tear resistant when treated with heat.

When producing needle punched nonwovens for thermal bonding, some of the fibers must be heat-sensitive in order for thermal bonding to be effective.

The needle punched material is fed through two or more nonwoven calendering rolls that are heated with oil or electrically to a precise temperature. The combination of heat and pressure generated by the calendering rolls forms a well-bonded needle punched nonwoven.